Engineered Rigging’s Rapid Bridge Replacement System enables railroads and their maintenance contractors to remove and replace a railroad bridge span in a single day. In addition to substantial time savings, the system also provides a safer method for bridge replacement than traditional hydraulic cylinder approaches. It is proudly engineered and manufactured with domestic materials in the U.S.A.

Unique Design

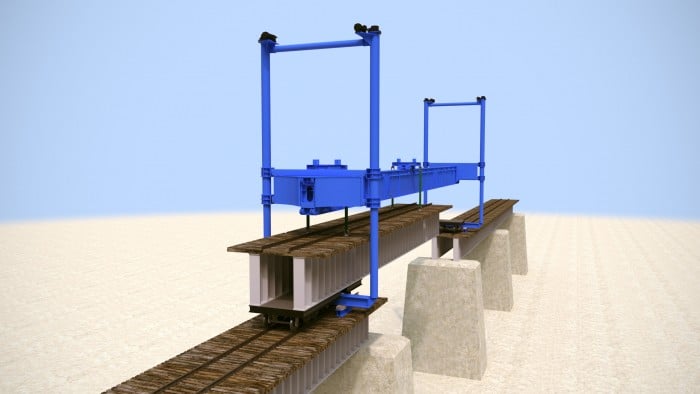

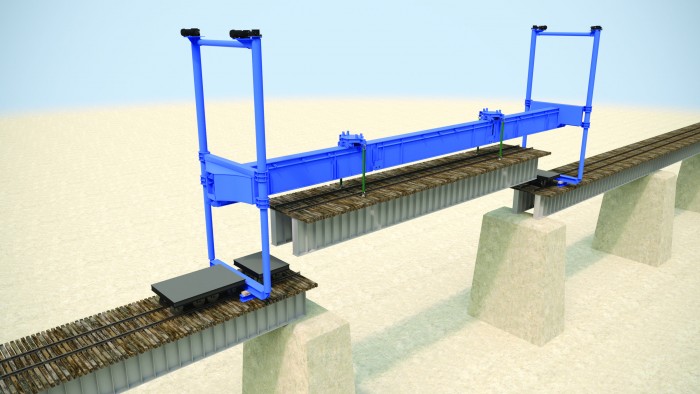

Engineered Rigging’s 250-ton Rapid Bridge Replacement System is comprised of four mechanically engaged lift columns (two at each end), a horizontal lift girder connecting the columns, drivable trolleys that guide the bridge span along the lift girder, and transport carts to carry away removed spans and deliver replacements.

- Top-of-Rails Design: installs on top of the rails, rather than under, eliminating the need for extensive below-rail modifications to adjacent sections

- Enclosed Lift Girder: doubles as a safe passageway, enabling crews to cross from one side of the bridge to the other once the span is removed

- Modularity: eases handling, shipping and setup

Easy Transport & Rapid Assembly

By setting up the system on a nearby spur, rail service is not interrupted during assembly. • Assembles in three to four shifts • Ships to rail spur on four to five legal flatbed trailers • Requires no wide load or heavy load permits

Safe, Fast Operation

Railroads can use the Rapid Bridge Replacement System to safely exchange a bridge span in just one day, significantly less time than hydraulic cylinder methods. Depending on the number of spans, railroads can safely and efficiently replace a complete bridge in days rather than months.

- Mechanically Engaged Lifting: no cable drums or strands that can fail or hydraulics that leak

- Self-Locking Lift Columns: perfectly synchronized lifting and positive mechanical engagement 100% of the time

- Power Failsafe: lift columns that maintain stability during power outage

- Remote Operation: lifting and transport controlled from a safe distance

Standard Configuration

The Rapid Bridge Replacement System features a 250-ton lifting capacity and is capable of replacing most railroad bridge spans. Engineered Rigging can customize the system to meet unique customer requirements. Components include:

• Four 30-foot lift columns • Two lift column connector beams • One central span box girder • Two adjustable ladders • Two trolleys and drive systems • Lift system transport carts • Bridge section transport carts • Synchronized control system with power unit

Compliance

Engineered Rigging’s Rapid Bridge Replacement System proudly complies with the applicable sections of the following standards:

• AISC Manual of Steel Construction, 9th Ed. and 13th Ed. • ASCE 7-10, Minimum Design Loads for Buildings and Other Structures • AWS D1.1, Structural Welding Code • 29 CFR 1926, OSHA Construction Industry Regulations